Motor Rewinding Works

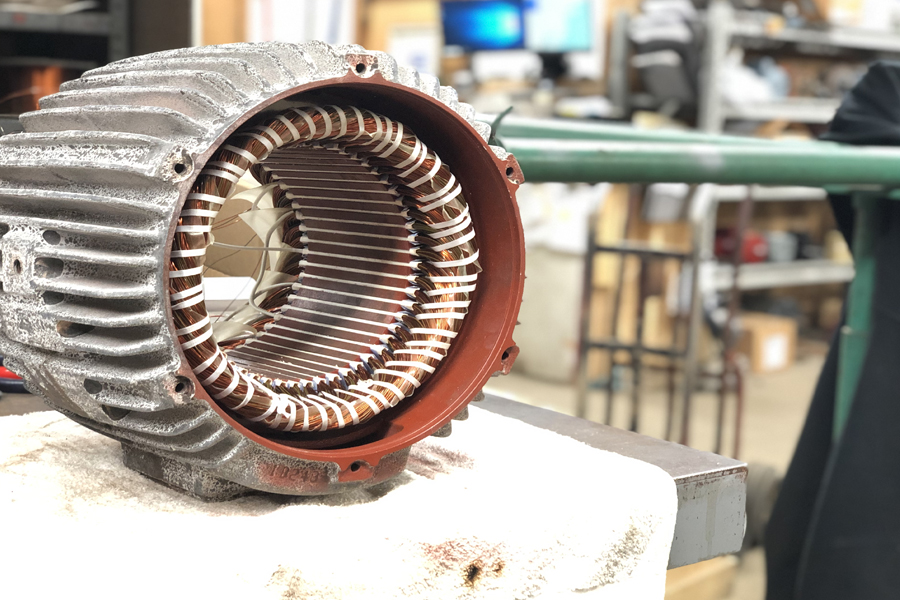

Motor rewinding is an essential process in the maintenance and repair of motors. It involves the replacement or repair of the motor windings, which are the copper wire coils that induce a magnetic field responsible for generating the rotational motion of the motor. To ensure efficiency and precision in this process, several types of motor rewinding equipment are employed.

Motor Coil Insulations

Insulation in motors serves to create a barrier between the conductive components and the stator, rotor, and housing. This barrier prevents electrical short circuits and mitigates the risk of equipment damage and user injury. By limiting the flow of electrical current to its intended path, insulation enhances the efficiency and performance of the motor. The insulation must withstand various stresses, including electrical, thermal, mechanical, and environmental, which underscores the importance of choosing the right insulation material.

The selection of the insulation class depends on the application's specific requirements, the expected motor load, and the environmental conditions under which the motor will operate. This classification system helps engineers and designers choose the most suitable insulation material for a given application, balancing performance, longevity, and cost.

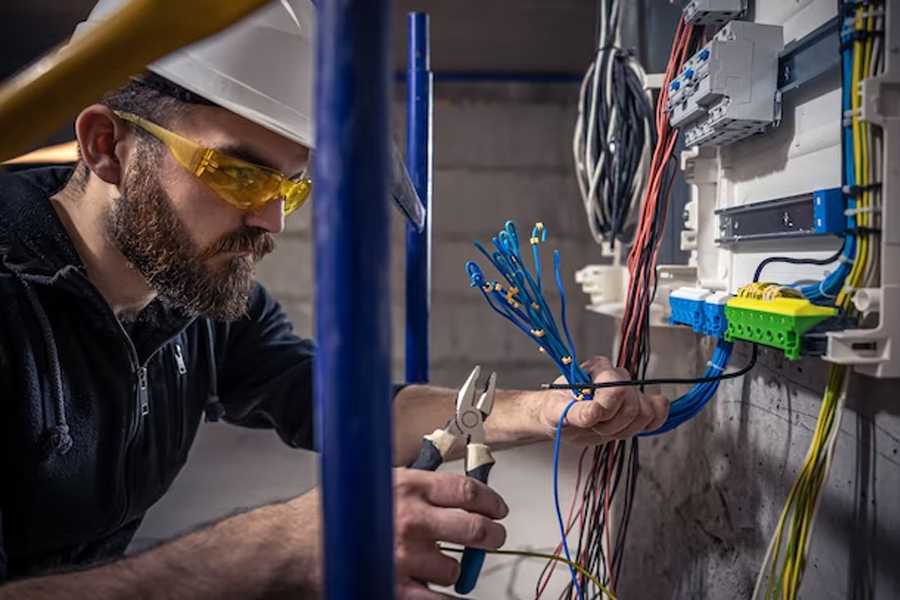

Motor Repairing & Servicing

Motor repair services rebuild and refurbish used motors. Some have cleanrooms and testing facilities, and certifications from the International Standards Organization (ISO) and original equipment manufacturers (OEMs). Motor repair services may specialize in rebuilding and refurbishing AC motors, DC motors, AC servomotors, DC servomotors, gearmotors, stepper motors, hydraulic motors, or linear motors. Some companies service a wide range of products. Motor repair services disassemble and clean motors, assess them for damage, and then repair or replace parts. Reassembly is also required. Depending on a motor's construction and condition, rewinding may be necessary. Servo motors are more complex than standard electric motors, and typically require motor repair services with specialized facilities and expertise.

All Types of Fixing Works

Structural systems transfer their loading through a series of elements to the ground. This is accomplished by designing the joining of the elements at their intersections. Each connection is designed so that it can transfer, or support, a specific type of load or loading condition. In order to be able to analyze a structure, it is first necessary to be clear about the forces that can be resisted, and transfered, at each level of support throughout the structure. The actual behaviour of a support or connection can be quite complicated. So much so, that if all of the various conditions were considered, the design of each support would be a terribly lengthy process. And yet, the conditions at each of the supports greatly influence the behaviour of the elements which make up each structural system.